Why do I need flux and how does it work?

In stained glass soldering, flux is a chemical agent that cleans the metal surfaces of the copper foil or lead came and prevents re-oxidation as it is heated. This preparation is essential for the molten solder to flow smoothly and create a strong, reliable bond with the metal.

Key functions of flux

- Cleans and etches: As a mild acid, flux chemically cleans the copper foil or lead came of any oils, grease, or corrosion. Without it, oxides form quickly when the metal is heated, creating a barrier that prevents the solder from bonding properly.

- Aids solder flow and "wetting": By removing contaminants, flux allows the solder to "wet" the surface, meaning it spreads evenly and adheres effectively. Without flux, the solder would bead up instead of flowing smoothly along the seam.

- Prevents re-oxidation: While the metal is being heated, the flux forms a protective barrier over the clean surface. This prevents new oxides from forming and compromising the joint before the solder can be applied.

How flux is used in stained glass

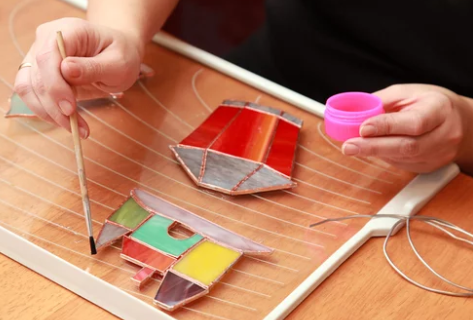

- Preparation: Before soldering, each piece of glass is wrapped tightly with copper foil tape, and the seams are burnished to ensure the best possible connection.

- Application: The flux is applied with a brush directly onto the copper foil or lead came where the solder will be applied. This is typically done in small sections just before soldering, as the flux can evaporate.

- Activation: The heat from the soldering iron activates the flux, causing it to remove the final layer of oxidation.

- Soldering: The solder is then melted along the seam, following the path of the active flux. The flux's chemical properties enable the solder to bond to the metal and create a smooth, elevated bead.

- Cleanup: After soldering, it is crucial to clean off all flux residue, as its acidic nature can cause corrosion over time. This is typically done with a water-based cleaner, such as a solution of water and baking soda, followed by a final wash.

Flux types by consistency

Liquid flux - is typically a zinc chloride-based formula that is thin and water-soluble.

Pros:

- Creates very smooth, shiny, and high solder lines.

- Goes on easily with a brush.

Cons:

- Prone to splattering hot solder, which can cause minor burns or leave small pockmarks on the glass.

- Because it's very thin, it can run and spread to areas you don't intend to solder.

- It evaporates quickly and may need reapplication during a long soldering session.

Gel flux - a newer innovation with a thicker, more viscous consistency.

Pros:

- Its thick consistency prevents splattering, making it safer to use.

- Stays exactly where it is applied and won't run.

- Produces excellent, consistent solder beads.

- Many formulas are water-soluble and easy to clean.

Cons:

- Can be more expensive than liquid flux.

- Because it is a specialty product, it may have a shorter shelf life than other fluxes.

Paste flux - has a thick, petroleum-based consistency.

Pros:

- Clings well to surfaces, making it great for three-dimensional projects like lamps.

- Stays active for a long time, allowing you to prep a large area before soldering.

Cons:

- Its residues are harder to clean than water-soluble fluxes and require special cleaners or solvents.

- Can produce more smoke and odor than other types.

Zinc chloride flux - a very active, acidic, and effective flux, common in many traditional formulations.

Pros:

- Very strong cleaning action, promoting excellent solder flow.

Cons:

- Highly corrosive and can damage the copper foil or lead came if not thoroughly cleaned.

- Produces more irritating fumes when heated.

Water-soluble organic acid (OA) flux - safer, less corrosive alternative to inorganic acid fluxes.

Pros:

- Less corrosive and irritating than zinc chloride formulas.

- The residues are easy to clean with water.

Cons:

- May not be as aggressively effective on heavily oxidized surfaces.

Choosing the right flux for your project

When choosing a flux, consider your project, skill level, and personal preferences:

- Beginners or those with sensitive skin: Gel flux is an excellent choice due to its non-splattering properties and ease of cleanup.

- Dimensional projects: Paste flux works well for lampshades and boxes because it won't drip or run.

- Experienced crafters: Liquid flux delivers the shiniest, smoothest seams but requires more care to avoid splatters.

- Regardless of type, always clean thoroughly: Even with "water-soluble" fluxes, some residue is always left behind. Use a flux remover or a baking soda and water solution to neutralize all remaining acid and prevent corrosion.